Automotive

Polymers have created a major revolution in the automotive sector. Polymer materials used instead of traditional metal parts significantly reduce the weight of vehicles, increase fuel efficiency and offer environmentally friendly solutions. Polymers, which are widely used in the interior and exterior parts of vehicles, stand out with their durability, flexibility and corrosion resistance properties. Especially critical parts such as bumpers, fuel tanks, dashboards and body parts are produced with polymers. In addition, seats, steering wheels and sound insulation materials that increase interior comfort also benefit from the advantages provided by polymers. Polymers both reduce costs and speed up production processes in the automotive sector.

Home Appliances

In the white goods sector, polymers increase both the aesthetic appearance and functionality of products. Polymers are used on the interior and exterior surfaces of household appliances such as refrigerators, washing machines, dishwashers and ovens. These materials are both impact resistant and resistant to heat and chemicals. In addition, the lightness provided by polymers facilitates the transportation and installation of white goods. The insulation properties of polymers also increase energy efficiency, which supports both environmental awareness and consumer savings. Polymers are indispensable for producing long-lasting, durable and aesthetically appealing white goods.

Electrical & Electronics

In the electrical and electronics sector, polymers play a critical role in improving the performance and safety of devices. Polymer materials are widely used in cable coverings, sockets, switches, plugs and electronic device cases due to their high insulation properties. The protection of electronic circuits and the isolation of devices from external factors are among the advantages provided by polymers. In addition, polymers that are resistant to heat and chemicals ensure that devices operate safely. With their lightness and durability, polymers contribute to making portable electronic devices thinner, lighter and more durable. In addition, thanks to polymers, production costs are reduced and products are provided with a long life.

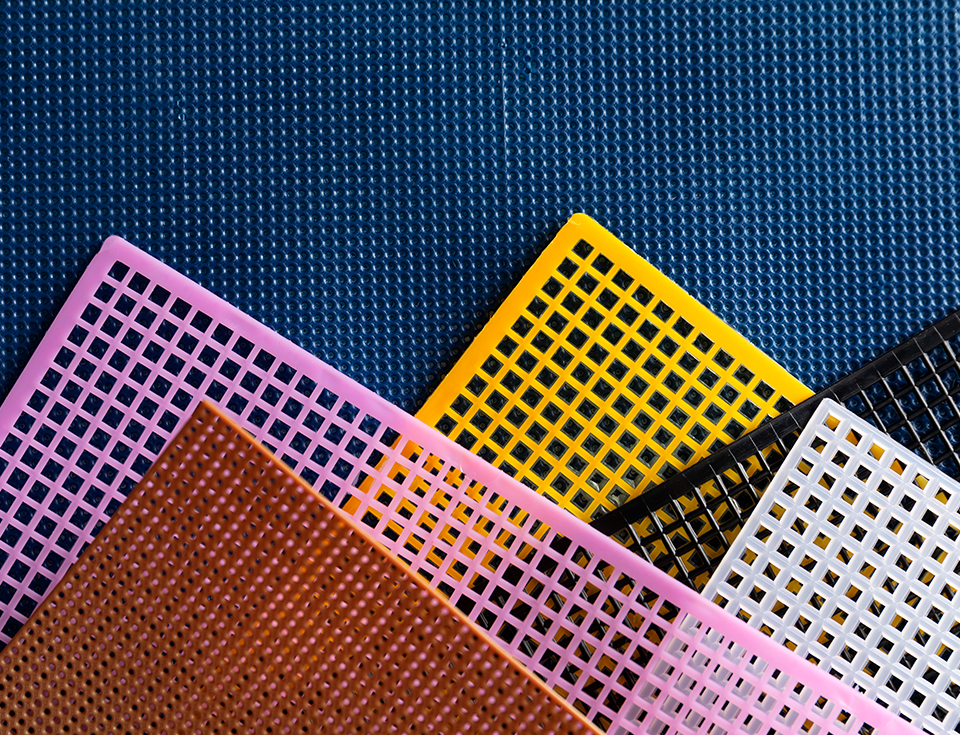

Construction

Polymers offer significant advantages in terms of longevity and durability in the construction sector. Polymers used in construction materials increase the structural integrity of buildings while also reducing maintenance and repair costs. Polymers are preferred in many areas from pipe systems to window frames, roof coverings to floor coverings. These materials are highly resistant to water, chemicals and weather conditions, which increases the durability of buildings. In addition, lightweight polymer materials facilitate transportation and assembly processes and shorten construction periods. The flexibility and formability provided by polymers allow for more creative designs in modern architecture.

Packaging

In the packaging sector, polymers are indispensable materials for protecting and transporting products. Thanks to their flexibility and lightness, polymers can be used in the packaging of all types of products, from food to electronic devices. In food packaging, the high barrier properties of polymers prevent food spoilage by extending the freshness and shelf life of products. In addition, recyclable polymers offer environmentally friendly packaging solutions and contribute to sustainability goals. The transparency of polymers allows products to be visible through the packaging, which provides information about the product to the consumer while also providing an aesthetic packaging design.

Furniture

In the furniture sector, polymers offer durable and aesthetically appealing products. Polymer materials are used in the production of furniture such as tables, chairs, and cabinets, providing both cost efficiency and making it possible for products to be lightweight. Polymers provide a variety of color and texture options, allowing furniture to be visually enriched. In addition, the fact that polymers are resistant to water and stains ensures that furniture is long-lasting. UV-resistant polymers, especially used in outdoor furniture, prevent the color of the products from fading. These materials also offer an environmentally friendly option thanks to their recyclability.

Small Home Appliances

In the small appliances sector, polymers play a critical role in the design and functionality of products. The lightness and processability of polymers ensure that appliances such as coffee machines, mixers, vacuum cleaners, and toasters, which are frequently preferred in daily use, are ergonomic and user-friendly. Polymers are used in the outer coatings, buttons and handles, and even internal mechanisms of these products, increasing both durability and reducing costs. Heat-resistant polymers ensure the safe use of small appliances. In addition, the wide range of colors and shapes provided by polymers encourage creativity in product design, thus offering consumers aesthetically appealing products.

Medical and Pharmaceutical

In the medical and pharmaceutical sector, polymers are critical materials that raise health standards and increase patient safety. Biocompatible polymers are used in many applications such as medical devices, implants, prosthetics and drug delivery systems. Sterilizable polymer materials improve patient care by minimizing the risk of infection. In addition, lightweight and flexible polymers are preferred in the production of ergonomic medical devices that increase patient comfort. The flexibility provided by polymers allows drug capsules and medical devices to be produced in the desired shape and form. These materials also facilitate access to healthcare services thanks to their low cost and wide production.

Toys and Home Products

Polymers play a key role in the production of both safe and aesthetically appealing products in the toy and home furnishings sector. Toys are manufactured from polymers that do not contain harmful substances such as BPA, with children's safety in mind. These materials allow for the production of long-lasting toys thanks to their durability. In addition, the flexibility of polymers offers a wide range of creativity in toy designs, which enables the development of fun and educational products for children. In terms of home furnishings, polymers are used in a wide range of areas from kitchenware to decorative products. Since polymer materials are resistant to water, stains and impacts, quality items that can be used at home for a long time are produced. These materials also provide endless options in terms of color and design, providing personalized and aesthetic solutions in home decoration.

Defense Industry

Polymers are used in the defense industry as materials that provide high performance and safety. Lightweight and durable polymers are preferred in many products such as military vehicles, weapons, armor and protective equipment. Polymer materials strengthen the armor of military vehicles while also increasing the maneuverability of the vehicles. In addition, polymers are used in personal protective equipment such as helmets and body armor that provide ballistic protection. The flexibility and high strength provided by polymers allow the development of innovative products in the defense industry. In addition, the corrosion resistance of polymers reduces the maintenance requirements of military equipment and provides long-lasting use.

Textile

In the textile sector, polymers increase the durability and functionality of fabrics. Fibers produced from synthetic polymers create flexible and lightweight textile products that are resistant to water and stains. In applications such as sportswear, outdoor clothing and workwear, the breathability, moisture management and quick-drying properties provided by polymers increase user comfort. In addition, polymer coatings can be applied to fabrics to provide special functions such as waterproofing or fireproofing. In the textile sector, polymers also play an important role in terms of recyclability and sustainability, which increases environmental awareness and offers consumers eco-friendly options.

Transportation

In the transportation sector, polymers play an important role in increasing fuel efficiency by reducing the weight of vehicles. Polymer materials are used in many types of vehicles, from airplanes to trains, buses to ships. Properties such as lightness, durability and resistance to corrosion make polymers indispensable in this sector. In particular, critical parts such as aircraft and automobile seats, interior panels, upholstery and safety equipment are produced from polymers. In addition, the flexibility provided by polymers allows more freedom in the design of transportation vehicles and increases aerodynamic performance. Polymers provide cost efficiency in this sector, while also increasing the safety and comfort of vehicles.